Heat Shrink Insulating Tubing

Application

1.Inoshandiswa kune yepakati voltage kusvika ku36kV

2.Kudzivirira pakunyorova uye kudzvinyirira

3.Inokodzera kubviswa kwetambo uye yepakati yekubatanidza kudzivirira kudzivirira

Feature

1.Hot melting adhesive inopa mvura iri nani

2.Coating type: film coating

3.Excellent corrosion resistance

4.UV kushorwa uye kusagadzikana kwemamiriro ekunze

5.Halogen-isina

6.Superior magetsi uye mechanical properties

7.Shrinkage ratio 3:1

8.Medium rusvingo

Feature

1.Inodiwa magetsi ekushandisa basa

2.Reliable insulation

3.Superior hermetic sealing

4.Excellent kupisa / kutonhora uchapupu, mvura, Anti-kukwegura ,

5.Inoshandiswa zvakanyanya pamunda wemagetsi emagetsi, emagetsi, peturu, makemikari engineering, kuvaka uye kutaurirana.

Kugadzirwa kwekupisa shrinkable tubing kunofanirwa kutanga kwasarudza yakakodzera masterbatch, uyezve sarudza izvo zvekubatsira zvinhu kugadzira chaiyo.

The thermal housing casing.

1. Kugadzirwa kwekupisa kunopisa chubhu ndiko kutanga kugadzirwa kwe polyene leech masterbatch: kubatanidza zvakasiyana-siyana zve polyene leech base zvinhu zvakasiyana-siyana zvinoshanda zvekubatsira.

Izvo zvinhu zvinoyerwa zvichienderana neformula reshiyo uye zvobva zvasanganiswa: izvo zvakasanganiswa zvinoiswa mumapatya-screw extruder uye pelletized kugadzira polyene leech inoshanda masterbatch.

2. Chigadzirwa chekuumba maitiro: maererano nechimiro chechigadzirwa, nzira mbiri dze single screw extrusion uye jekiseni molding inogona kushandiswa.

Kugadzirisa uye kugadzira:

1. Single-screw extrusion type: inonyanya kushandiswa kuumba extrusion yepombi dzekupisa dzinonyura, senge-single-wall heat-shrinkable chubhu, kaviri-madziro kupisa-shrinkable chubhu ane glue, uye ukobvu hwepakati.

Wall heat sink pombi, high pressure busbar heat sink pombi, tembiricha yekupisa inodzika pombi uye zvimwe zvigadzirwa zvese zvinogadziriswa uye zvinogadzirwa ne single screw extrusion.

Iyo inopisa inopisa chubhu yekugadzira tambo inofanirwa kuve neinotevera midziyo: extruder (kupisa kunyura chubhu kugadzira), kugadzira mold, inotonhorera tangi remvura, tension mudziyo, uye

Disk mudziyo, nezvimwe.

2. Injection molding: inonyanya kushandiswa kugadzira kupisa-shrinkable special-shaped parts, like heat sink caps, heat-shrinkable umbrella skirts, heat-shrinkable finger cots nezvimwe zvinogadzirwa.

Vese vanoshandisa jekiseni kuumba, uye zvigadzirwa zvekugadzira zvinofanirwa kusanganisira majekiseni ekuumba michina uye majekiseni mold.

3. Nhanho inotevera yakakosha ndeye radiation cross-linking.Zvigadzirwa zvinogadzirwa ne extrusion kana jekiseni molding zvichiri mutsara mamorekuru zvimiro.

Chimiro, chigadzirwa hachisati chave ne "memory function", uye kushanda kwekudzivirira kwekushisa, kuchembera kukwegura, uye kupfeka kuramba hakuna kukwana.

Shandura chimiro chemolecular chechigadzirwa.Nzira yatinowanzo shandisa ndeye radiation crosslinking modification: electron accelerator radiation crosslinking, cobalt source radiation.

Cross-linking, peroxide kemikari cross-linking, panguva ino molecule inoshanduka kubva pamutsara we molecular structure kuenda kune network.Zvigadzirwa zvakawedzerwa zviri kupfuura

Mushure mekuyambuka-kubatanidza, ine "memory effect", iyo inowedzera zvakanyanya kupisa kwekushisa, mechanical properties, uye makemikari ehutu hunopisa hunopisa.Tafura chaiyo

Ikozvino kupisa kunyura chubhu yachinja kubva kumamiriro ekushivirira kuenda kune isingaenderane, kuchembera kuramba, abrasion resistance, uye chemical corrosion resistance.

4. Kuwedzera kuumbwa: Chigadzirwa chakagadziridzwa nemwaranzi crosslinking chatova ne "shape memory effect", uye chine yakakwirira.

Kusanyunguduka kwekuita pasi pekushisa.Mushure mekupisa pakupisa kwepamusoro, vacuum kuvhuvhuta uye kutonhora, inova iyo yakapedzwa kupisa inoputika chubhu, uyezve zvinoenderana nechubhu.

Mamiriro chaiwo echigadzirwa chakapedzwa kurongedza nekuvhara zvinogona zvakare kutemwa uye kudhindwa zvinoenderana nezvinodiwa nevatengi.Neutral normal packaging inowanikwawo.

Performance

| Test | Test Method | Zvinodiwa |

| Kushanda tembiricha | UL 224 | -50 kusvika +125 ℃ |

| Kusimba simba | ASTM D 2671 | ≥14 Mpa |

| Elongation panguva yekuzorora | ASTM D 2671 | >400% |

| Elongation panguva yekuzorora mushure mekupisa kuchembera | ASTM D 2671 158℃/168hrs | ≥300% |

| Longitudinal shrinkage | UL 224 | 0±5% |

| Partial wall rate | ASTM D 2671 | <30% |

| Flame retadancy | VW-1 | Pass |

| Volume resistivity | IEC 93 | >1014Ω.m |

| Copper kugadzikana | UL224 | Pass |

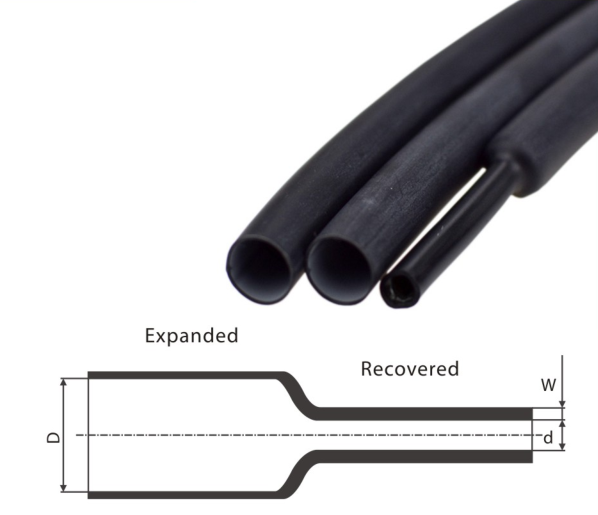

| Type | Chishandiso Diameter Range(mm) | Yakawedzerwa(mm) | Yadzorerwa(mm) | |

| D(min) | d(max) | W(min) | ||

| RSG-15/5 | 4.5-8 | 15 | 5 | 1.5 |

| RSG-20/8 | 6.5-14 | 20 | 8 | 1.8 |

| RSG-28/10 | 12-18 | 28 | 10 | 1.8 |

| RSG-35/14 | 17-27 | 35 | 14 | 2 |

| WRSG10-28/10 | 6.5-14 | 28 | 10 | 2.2 |

| WRSG10-34/14 | 17-27 | 34 | 14 | 2.3 |

| WRSG10-40/18 | 17-30 | 40 | 18 | 2.5 |

| WRSG10-50/20 | 17-35 | 50 | 20 | 2.5 |

| WRSG35-50/20 | 17-35 | 50 | 20 | 3 |

| WRSG35-60/22 | 21-45 | 60 | 22 | 3 |

| WRSG35-70/25 | 24-52 | 70 | 25 | 3 |