Chii chinonzi Socket Clevis?

Socket clevis inozivikanwawo se socket rurimi chinhu chakakosha cheiyo pole line tekinoroji.

Inowanzoshandiswa pamitsetse yepamusoro, mitsara yekutumira, uye tambo dzemagetsi.

Icho chinhu chikuru mu pole line hardware iyo inowanzobatanidza socket type insulator uye tension clamp.

Tarisa izvi:

Kubatana kwesocket clevis kunosiyana munyika dzakasiyana zvichienderana nemitemo inotonga pole line tekinoroji.

Saka, zvakakosha kuti uzive kubatana munyika yako usati wafunga kuisa odha yehardware.

Semuenzaniso, muAfrica mhando yesocket clevis inoshandiswa inosanganisira:

Socket rurimi rwakashandiswa zvakakodzera pa "Aluminium Conductor Steel Reinforced (ACSR)".

Iyo dhayamita yekunze iri pakati pe7mm ne18.2mm (25 square millimeters uye 150 square millimeters).

Yakashandiswawo pa "standard disc insulators yebhora uye socket type" ine dhayamita yepini yebhora ye16 mm.

Sei Uchida Socket Clevis?

Sechikamu chakakosha che pole line hardware, socket clevis inoshandiswa kune zvimwe zvinangwa.

- Iyo inobatanidza socket type insulator uye tension clamp kana tsigiro.

- Inoshandiswa seyakakodzera mukubatanidza insulators yetambo imwe.Mienzaniso inosanganisira "bhora uye socket, clevis uye rurimi zvinobatanidza, mahwendefa ejoko emagetsi ane tambo dzakawanda."

- Inogonawo kushandiswa pamagetsi emagetsi sekubatanidza magetsi.

- Mumitsetse yepamusoro, inoshandiswa sechikamu chakakosha chekupa simba remagetsi kuzvitima, mabhazi etrolley, uye tram.

- Mumitsara yekufambisa, chikamu chehurongwa hwakagadzirirwa kubatsira mukuitisa mamwe mafungu mumaredhiyo.

Zvikamu Zvikuru zveSocket Clevis

Socket clevis isangano rezvikamu zvakasiyana uye zvikamu.

Kunyange zvazvo zvakasiyana mumagadzirirwo uye maumbirwo, hezvino zvimwe zvezvikamu zvakajairika.

1. Zvisungo zveAnchor

Icho chidimbu chesimbi chinowanzo umbwa neU uye chakachengetedzwa nepini yeclevis uye bhaudhi.

Zvakare, inogona kuchengetedzwa uchishandisa hinged simbi loop ine kukurumidza kuburitsa yekuvhara pini michina.

Inoita sechinhu chikuru chinongedzo mune dzakasiyana dzekubatanidza masisitimu sezvavanopa kukurumidza kubatanidza uye kudimbura.

2. Clevis pin

Icho chikamu chakakosha checlevis fastener ine zvinhu zvitatu zvakakosha zvinosanganisira clevis pin, clevis, uye tang.

Mapini acho ndeemhando mbiri dzinosanganisira dzisina kuverengwa uye dzine threaded.

Mapini asina kuverengwa ane musoro wakaita dome kumucheto uye kune rumwe rutivi, kune gomba remuchinjikwa.

Kuchengeta pini yeclevis panzvimbo, pini yakatsemuka kana pini yecotter inoshandiswa.

Pini yakarukwa kune rumwe rutivi yakagadzira misoro kune rimwe divi asi rimwe divi richingoitwa shinda.

Nzungu inouya inobatsira kana pini ichifanirwa kuiswa panzvimbo.

3. Clevis bhaudhi

Inogona kushandiswa kuita panzvimbo yepini yeclevis kunyangwe isingatore kushushikana kunoitwa nepini yeclevis.

Ivo vanoitwa kuti vatore uye vachengetedze tension mitoro.

4. Pini yeCotter

Iyo inozivikanwawo sepini yekupatsanura zvichienderana nenyika yairi kushandiswa mairi.

Rangarira, ichi chimedu chesimbi chinoshanda sechisungo chine migumo yakakombamira pakuiswa.

Inoshandiswa pakusunga zvidimbu zviviri zvesimbi pamwechete.

5. Bolt

Imhando yefastener ine tambo dzekunze dzechirume dzinoshandiswa uye dzine zvakafanana kune screw.

Inowanzoshandiswa pamwe chete ne nut.

Kune rumwe rutivi kune musoro webhaudhi uye kune rumwe rutivi kune kunze kwechirume shinda.

6. Nut

Iyi imhando yefastener ine buri rine thread.

Inoshandiswa pamwe chete nebhaudhi kusungira kana kubatanidza zvikamu zvakasiyana pamwechete.

Kudyidzana kunoiswa pamwe chete nekubatanidzwa kweshinda kuburikidza nekukweshana.

Kunze kweizvozvo, zvinoenderana nekutambanudza uye kudzvanywa kwezvikamu zvakabatanidzwa pamwechete.

Unyanzvi Kutsanangurwa kweSocket Clevis

Usati watenga socket clevis, zvakakosha kuti utarise kune anotevera akakosha tekinoroji maitiro:

1. Rudzi rwezvinhu

Mhando yezvinhu zvinoshandiswa mukugadzira socket clevises isimbi nesimbi.

Zvinhu izvi zvinofarirwa nekuti zvine simba zvakakwana uye zvinokwanisa kumira nehuremu nekushushikana.

2. Surface Treatment

Socket clevises inopfuudzwa nenzira yekupisa dip galvanization kuti iite kuti irambe corrosion.

Kupisa dip galvanization kunosanganisira kunyudza simbi kana simbi clevis mu zinc kuti ipure uye nekuipa iyo yekupedzisira yakatsetseka kubata.

Simbi nesimbi zvinogezwa muzinc yakanyungudutswa patembiricha ye449 degrees Celsius.

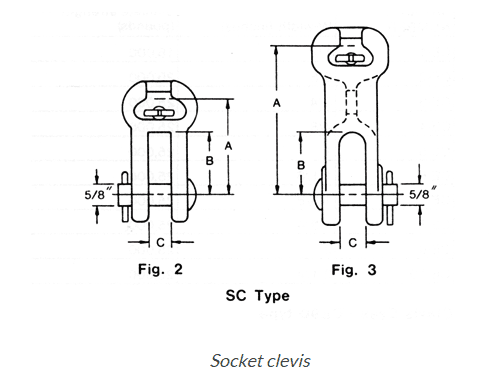

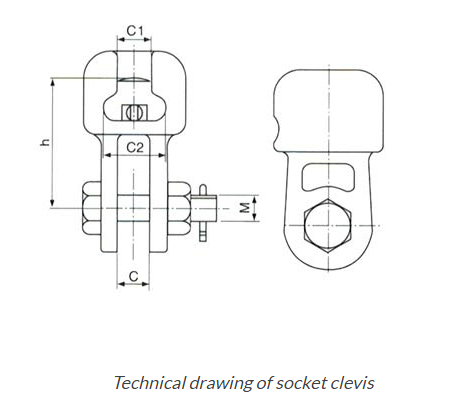

3. Dimensions

Zviyero pane socket clevis zvinosiyana zvichienderana nehukuru hwechishandiso.

Zvakare, iyo yakakura saizi ye socket clevis ndiyo yakakura zviyero.

Hupamhi nehurefu zvinopimwa nemamilimita ukuwo huremu hunotarwa nemakirogiramu.

4. Dhizaini

Dhizaini pane socket clevis inoenderana nekambani inoigadzira.

Kazhinji, mutengi ane revo mumhando yekugadzira iyo yaachazoda uye kune basa, raizoita.

Dhizaini ye socket clevis inofanirwa kuenderana nebasa rayaifanirwa kuita.

5. Yakatemerwa Mutoro

Iyo yakatemerwa mutoro pane socket clevis zvinoenderana nehuwandu hwesimba rauchabata.

Mutengi anofanira kutsanangura basa richaitwa neclevis asati atenga clevis.

Mugadziri anozopa zano pane yakanyatsokodzera socket clevis maererano neyakayerwa mutoro.

6. Kurema

Huremu hwe socket clevis zvinoenderana nehukuru hwechishandiso, zvinhu zvinoshandiswa mukugadzira mudziyo.

Zvimwe zvinhu zvinorema kupfuura zvimwe zvichikonzera musiyano mukuru mukurema.

Zviyero zvakaita sehupamhi, kureba zvinosiyana uye saka huremu hunosiyana.

Socket Clevis Manufacturing Process

Maitiro ekugadzira anotanga nekudziya, kuumba, kupinza uyezve kupisa dip galvanization.

Maitiro ataurwa pamusoro ane njodzi uye anowanzo kusiiwa kuti maindasitiri aite.

Zvishandiso: iyo huru mbishi inodiwa isimbi uye mold ye socket clevis.

Mimwe michina inodiwa pakuita uku inodhura zvakanyanya.

Ichi ndicho chikonzero nei ichisiiwa kuti maindasitiri makuru akaita seJingyoung agadzire.

Kuchenjerera: Maitiro ekugadzira clevis anosanganisira kubata iron pane tembiricha yakanyanya.

Iyi inzira ine ngozi uye unofanira kungwarira pakubata simbi yakanyungudutswa.

Iwe unofanirwawo kupfeka zvipfeko zvekudzivirira uye bhutsu kukudzivirira kubva kune chero njodzi dzinogona kuitika.

Zviyero: Iyi ndiyo nzira yekuwana hukuru hwakakodzera hwezvinhu kuti zvishandiswe mukugadzira.

Izvo zvinoitwa zvinoenderana nezvinodiwa nemutengi kana kune tsika-yakagadzirwa socket clevises.

Nyaya yacho inochekwa kuita zvidimbu zvinodiwa isati yaiswa kune mamwe maitiro.

Heating Process: Cast iron inodziiswa pakupisa kwakanyanya kuti inyunguduke.

Cast iron ndiyo inonyanya kufarirwa zvinhu nekuti inonyunguduka nekudzikira tembiricha kana ichienzaniswa nemamwe.

Inoshandurwa kubva kune yakasimba kuenda kune yemvura.

Simbi yakanyungudutswa inopisa kwazvo uye kungwarira kwakawanda kunofanirwa kutorwa panguva iyi.

Kunze kwekunyungudika kwakaderera, simbi yakakandwa ine fluidity yakanaka, yakanakisa machinability, kupfeka kuramba uye kusagadzikana deformation.

Izvi zvivakwa zvinoita kuti ive inonyanya kufarirwa zvinhu zvinoshandiswa mukugadzira socket clevis.

Kuumba: Simbi yakanyungudutswa inobva yadirwa muforoma ye socket clevis.

Iyo mold yakaumbwa nenzira yekuti ine buri rakafanana nerurimi rwesocket.

Liquid iron inotora chimiro che mold inova chimiro che socket clevis.

Annealing: Nhanho yechitatu ndeye annealing inova nzira yekupisa kupisa iyo inoshandura microstructure yesimbi.

Iwo maitiro anoita kuti socket clevis iwane simba rayo, kuoma, uye ductility.

Kutonhodza: danho rechina rinosanganisira kusiya simbi yakaumbwa kuti itonhore.

Kutonhodza kunononoka kubvumira mold kuti igare muchimiro uye kuti isatsemuka.

Kupisa dip galvanization ndiyo nzira yekupedzisira iyo simbi yakatonhorera inotorwa kuburikidza nayo.

Izvi zvinosanganisira kuvhara socket clevis uchishandisa Zinc kuidzivirira kubva mukuora.

Iyo socket clevis inonyikwa mu zinc yakanyungudutswa patembiricha ye449 degrees Celsius.

Panguva ino, socket clevis yakagadzirira uye inoongororwa kuti ione kuti yakanakira kushandiswa.

Maitiro ekuisa Socket Clevis?

Kuiswa kwesocket clevis inzira inoda kuti iwe uve nemapango panzvimbo usati waedza kuisa.

Iva nechokwadi chekuti zvinhu zvese zviri panzvimbo zvakare uye manera aripo ekukwidziridza iwe kusvika pakakwirira inodiwa.

- Tambo dze insulator dzinofanira kuunganidzwa pasi dzisati dzakwira padanda.Kubatanidza tambo pasi kuri nyore kana zvichienzaniswa nekuzviita pamusoro pedanda.

- Iyo insulators uye mafittings akaiswawo pasi uye zvakare pakakwirira.

- Kuti kuwedzere kushanda kwekugadzirisa, kunyanya kana mamiriro ekuvaka aripo, gungano revhu rinosarudzwa.

- Gungano panzvimbo yakakwirira inoitwa kana kuvaka kune zvirambidzo.

- Panguva yekugadzwa kwema insulators uye mafittings pakakwirira, vashandi vanotakura maturusi, tambo uye matepi esimbi kumusoro kwemanera.

- Nzvimbo yekuisa ruoko rwemuchinjikwa yakanyorwa uye nerubatsiro rwetambo, inodhonzwa.

- Ruoko rwemuchinjikwa rwakaiswa panzvimbo ipapo mamwe mahardware senge insulator uye insulator tambo dzinoiswa.

Iyo socket clevis chinhu chakakosha cheiyo pole line hardware uye inoiswa nenyanzvi.

Rudzi rwebasa rinotarisirwa kuita rinoda kuti vanhu vane ruzivo vaise sezvo kukanganisa kusingagamuchirwe.

Zvine njodzi zvakare kuedza kuisa pasina rubatsiro rwevamwe vanhu zvichireva kuti hazvigone kuitwa wega.

Nguva yekutumira: Sep-17-2020